LEXAN™ polycarbonate film stands out for its superior printability, durability, and adaptability across a broad spectrum of printing projects, earning it the favor of printers, converters, and manufacturers in pursuit of premium printed materials boasting outstanding performance attributes.

Indeed, LEXAN™ polycarbonate film is a multifaceted substrate ideal for numerous printing projects, thanks to its remarkable transparency, stable dimensions, and robustness. The following outlines various printing techniques well-suited for LEXAN™ polycarbonate film:

Screen Printing: This technique allows LEXAN™ polycarbonate film to be adorned with vivid colours and complex patterns. The film's smooth texture and exceptional dimensional stability contribute to accurate alignment and uniform print outcomes, making it a go-to choice for items like labels, interface overlays, membrane switches, and graphical overlays.

Screen Printing: This technique allows LEXAN™ polycarbonate film to be adorned with vivid colours and complex patterns. The film's smooth texture and exceptional dimensional stability contribute to accurate alignment and uniform print outcomes, making it a go-to choice for items like labels, interface overlays, membrane switches, and graphical overlays.

Digital Printing: Compatible with modern digital printing methods, including UV-curable, solvent, eco-solvent, and latex prints, LEXAN™ polycarbonate film's high clarity and smoothness facilitate the creation of detailed visuals and texts with precision and vibrancy. This method is typically employed for producing signs, displays, promotional materials, and architectural visuals.

Offset Printing: For mass-produced print items such as labels, decals, nameplates, and insert packaging, LEXAN™ polycarbonate film proves ideal due to its dimensional stability and tolerance to heat, qualities that are essential for offset lithography's demands. This results in consistently high-quality prints with accurate colour representation.

Flexographic Printing: LEXAN™ polycarbonate film can be flexo-printed for applications requiring fast production speeds and efficient ink transfer. Its smooth surface and excellent ink adhesion properties ensure sharp and durable prints, making it suitable for labels, packaging, and industrial applications.

Flexographic Printing: LEXAN™ polycarbonate film can be flexo-printed for applications requiring fast production speeds and efficient ink transfer. Its smooth surface and excellent ink adhesion properties ensure sharp and durable prints, making it suitable for labels, packaging, and industrial applications.

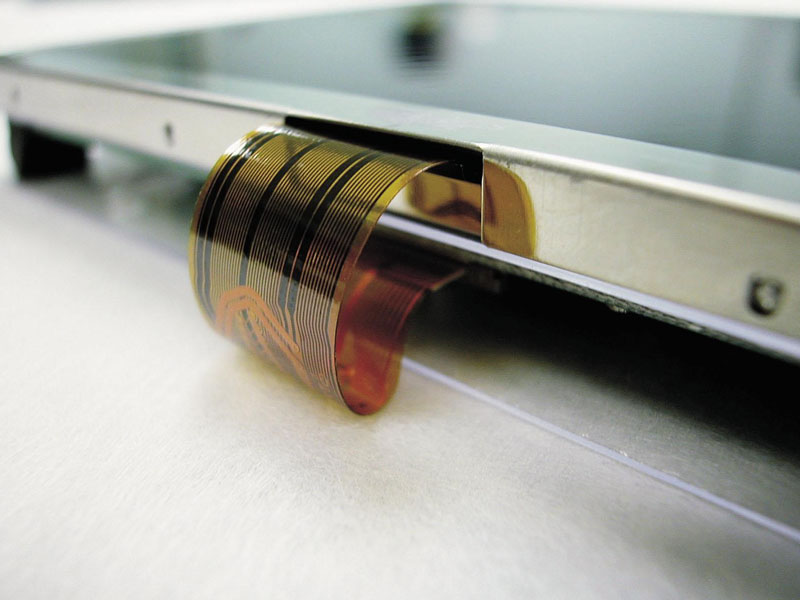

In-Mold Decoration (IMD): LEXAN™ polycarbonate film is suitable for in-mold decoration of molded plastic parts in automotive interiors, consumer electronics, appliances, and consumer goods. Its ability to withstand high temperatures, abrasion resistance, and printability allow for the direct transfer of graphics onto the surface of molded parts, resulting in durable and visually appealing decorations.

Security and Identification: LEXAN™ polycarbonate film can be used for printing security features, authentication tags, and identification cards requiring tamper resistance and durability. Its tear resistance, chemical resistance, and ability to withstand harsh environments make it suitable for applications requiring secure and reliable identification solutions.

Automotive Interior Components: LEXAN™ polycarbonate film can be utilized for printing automotive interior components such as instrument panels, center consoles, and decorative trim. Its scratch resistance, dimensional stability, and printability allow for the creation of customized and durable interior components with high-quality graphics and finishes.

Automotive Interior Components: LEXAN™ polycarbonate film can be utilized for printing automotive interior components such as instrument panels, center consoles, and decorative trim. Its scratch resistance, dimensional stability, and printability allow for the creation of customized and durable interior components with high-quality graphics and finishes.

Medical Devices and Equipment: LEXAN™ polycarbonate film can be used for printing labels, overlays, and control panels for medical devices and equipment. Its biocompatibility, chemical resistance, and printability make it suitable for applications requiring compliance with regulatory standards and durability in medical environments.

To learn more please visit our LEXAN™ sheet product pages:

Biggest Supplier & Authorised Distributor

Offering more than 50 grades of LEXAN™ Polycarbonate Sheets